Call:

0577-85859117

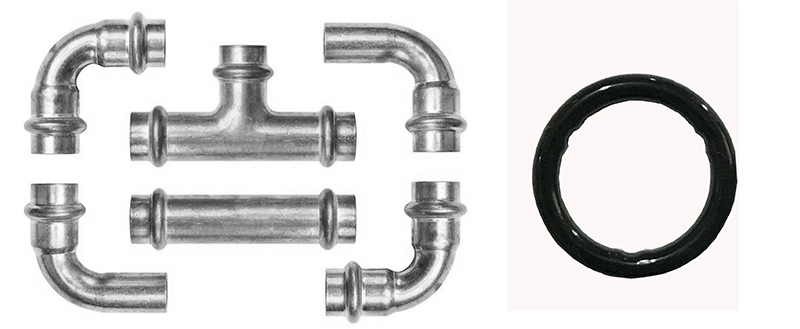

During the installation of press system, there may happen the press fitting connections are forgotten to press by the workers, which leading big problems. Since Coweth develops LBP o-rings, when the workers test the pressure at last after pressing installation, the left unpressed connections are easily found so that avoid the lost of un-appropriate operation and reduce the cost.

The O-ring is the synthetic rubber element that ensures the hydraulic seal on the joint between the pipe and fitting in pressfitting systems. The LBP solution, designed and patented by Coweth, ensures a perfect seal and makes it easy to identify unpressed fittings.

There are various types of trickle o-rings on the market. In comparison to these, Coweth solution has the following advantages:

For diameters greater than 54 mm, the "trickle" function is ensured by the use of the standard o-ring, also tested in compliance with Worksheet DVGW 534.

Our LBP o-rings are certified with WARS, DVGW, DTI, etc, supplied by many famous o ring manufacturers, like technogoma, maifeng, bode, etc.

For more information on LBP o-rings, you can contact the technical office directly at:info@jordith.com